In the last article, we’ve discussed what is GMP and its role to help food manufacturers to produce foods which are safe for human consumption. However, the safety of food packaging is just equally important as the safety of the food itself.

Food safety is greatly influenced by its packaging. GMP requirements specify that the packaging must be safe and suitable for its intended use.

Types of Packaging

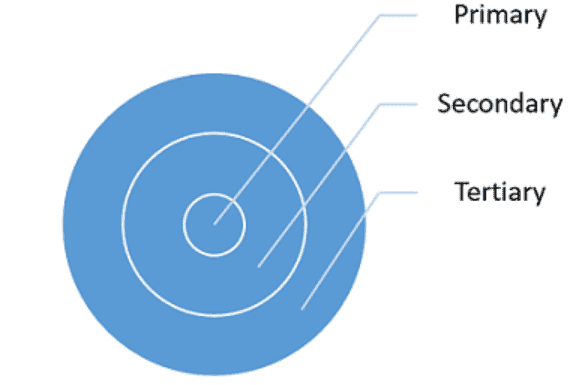

There are three types of packaging: primary, secondary, and tertiary. Each type of packaging has unique requirements, risks, and intended use(s).

- Primary package: main package (plastic bags/ bottles/ cans) that holds the food product that is seen at the point of sale.

- Secondary package: assembles the primary packages into a single container (ex: cardboard box with a number of identical products inside)

- Tertiary packaging: assembles all of the secondary packages into single pallet/ container/ carton box to allow easier shipping, warehousing and transportation.

Can food packaging companies implement GMP?

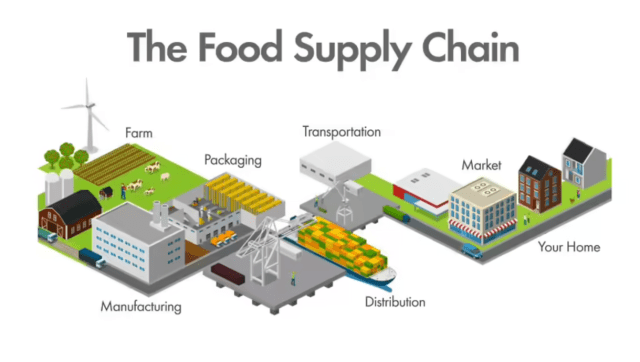

The answer is YES! In fact, GMP is applicable for any parties in the food supply chain such as farmers, raw materials manufacturers, food processers, packaging companies, distributors, transporters, retailers etc.

Why implementing GMP is beneficial for food packaging companies?

Proper packaging safeguards your food product against physical damage as well as chemical and microbiological contamination. Nonetheless, food package itself could become a source of contamination to the foods if the packaging material was not manufactured under well-controlled and hygiene environment.

A food manufacturer that implements food safety system is required to implement Quality Control procedure for incoming packaging material before acceptance. Any sign of contamination on the packaging material shall be rejected and not to be used to hold any food product. GMP can help food packaging companies to significantly reduce the risks of contamination by establishing well-regulated, hygienic and safe environment.

Food manufacturer who also complies with GMP is required to assess and evaluate their food packaging supplier to ensure the safety of the packaging material. That also means if you are a manufacturer of packaging material, getting GMP certification would significantly increase the confidence of your customers towards your packaging products and possibly attract more new customers.

Conclusion

Establishing and implementing GMP in your packaging business is an extensive undertaking which requires commitments, efforts and budget. Yet, it is undoubtedly among the most important and rewarding things any packaging business can do to ensure safe, consistent products and compliance.

Wish to know more about GMP implementation? Book our limited FREE Consultation right now!